Product Description

OEM High Precision Steel Casting Electric Car Service

Product Description

1. Precision CNC machining parts strictly follow customers’ drawing, packing, and quality requirements.

2. Tolerance: between+/-0.01mm;

3. The high-tech CMM inspector to ensure the quality;

4. Full-Experienced engineers and well professional trained workers;

5. Fast delivery time;

6. Professional advice for our customers;

Detailed Photos

Product Parameters

Our advantage of cnc machining:

| Business Type | Beyond the Manufacturer and strong Milling Machining Parts organized ability in the industrial |

| Benefits | 1. Deeper industrial experience at CNC machining parts service for more than 10-years,our customer’s requirement is our 1st priority. 2. 2D or 3D files is available; 3. We trust the quality priority and we insist the good quality should be based on the customers’ satisfied; 4. Without any MOQ requirement; 5.Faster delivery time; 6. Customized size and specification /OEM available 7. Near ZheJiang Port |

The material

| Materials Accept |

Stainless Steel | SS201, SS303, SS304, SS316 etc. |

| Steel | Q235, 20#, 45#, | |

| Brass | C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37) , C28000(CuZn40) | |

| Iron | 1213, 12L14,1215 etc. | |

| Bronze | C51000, C52100, C54400, etc. | |

| Aluminum | Al6061, Al6063,AL7075,AL5052 etc | |

| Plastic | ABS,POM,PC(Poly-Carbonate),PC+GF,PA(nylon),PA+GF, PMMA(acrylic)PEEK,PEI etc) |

Packaging & Shipping

- We prefer DHL or TNT express or other air freight between 1kg-100kg.

- we prefer sea freight more than 100kg or more than 1CBM

- As per customized specifications.

Company Profile

About us

HangZhou CHINAMFG Technology Co.,Ltd is located in HangZhou City, ZheJiang Province, Which closed the ZheJiang .The Emitech Technology is mainly engaged in the CNC Machinery Industrial Service for 15 years. Our Parts are sold to Europe, America, Japan, South Korea and China in various kinds of industrial.At present, Our company has CNC Turning machines and CNC centers and equip with professional quality and testing instruments.We have full OEM Experience from worldwide, providing them with One-stop solutions for a broad range of applications.We look CHINAMFG to cooperating with you!

Our Advantages

1. Precision CNC machining parts strictly follow customer’s drawing,packing and quality requirement.

2. Tolerance: between+/-0.01mm;

3. The high-tech CMM inspector to ensure the quality;

4. Full-Experienced engineers and well professional trained workers;

5. Fast delivery time;

6. Professional advice for our customers;

After Sales Service

Iso9001 certified CHINAMFG cnc parts

We usually provide 12 Months repair service. If our duty, we will respond to send the new parts.

Our Service

| Our Processing | CNC center, CNC milling, CNC turning, drilling, grinding, bending, stamping, tapping, |

| Surface finish | Polishing, sandblasting, Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, |

| Tolerance | 0.05mm~0.1mm |

| QC System | 100% inspection before shipment |

| Drawing format | CAD / PDF/ DWG/ IGS/ STEP |

| Packaging | Plastic bag/Standard package / Carton or Pallet / As per customized specifications |

| Payment Terms | 30 -50%T/T in advance, 70-50% balance before delivery; Pay Pal or Western Union is acceptable. |

| Trade terms | EXW, FOB, CIF, As per the customer’s request |

| Shipment Terms |

1)We prefer DHL or TNT express or other air freight between 1kg-100kg. 2) we prefer sea freight more than 100kg or more than 1CBM |

| Note | The CNC machining parts are usually custom-made based on the customer’s drawings and samples. So we need the Down Payment |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

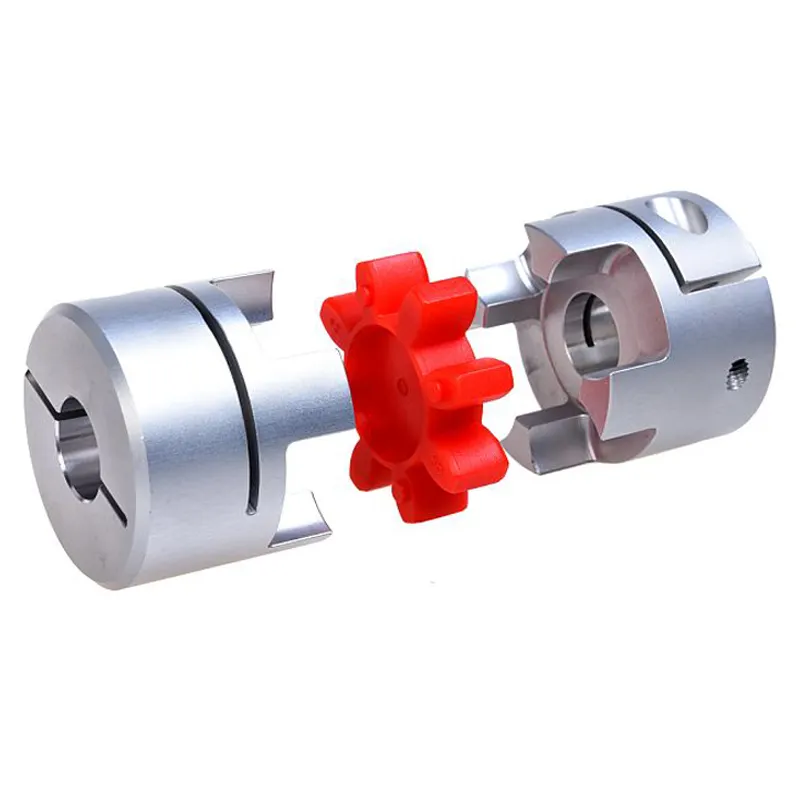

Minimizing Wear and Tear on Connected Components with Jaw Couplings

A jaw coupling plays a critical role in minimizing wear and tear on connected components by providing several key benefits:

- Shock Absorption: Jaw couplings have a flexible elastomeric element between the two hubs, which acts as a cushion and absorbs shocks and vibrations. When the connected machinery experiences sudden jolts or impacts, the jaw coupling helps dampen these forces, protecting the equipment from damage and reducing wear on components.

- Misalignment Compensation: In mechanical systems, misalignment between shafts is a common issue that can lead to premature wear on components. Jaw couplings can tolerate a certain degree of angular, parallel, and axial misalignment, allowing for better alignment between the driving and driven components. This feature helps distribute forces more evenly and reduces stress on connected components.

- Resilience to Overloads: Jaw couplings can withstand temporary overloads, such as starting torque or sudden load spikes, without causing damage to the connected equipment. The elastomeric element of the jaw coupling acts as a torque limiter, protecting the machinery from excessive loads and preventing wear and tear.

- Backlash Prevention: Backlash, which is the play or clearance between mating gears or components, can cause impact forces during reversing motions. Jaw couplings offer low backlash performance, reducing the potential for impact and minimizing wear on gears and other components.

- Reduced Maintenance: By providing shock absorption, misalignment compensation, overload protection, and low backlash, jaw couplings help extend the service life of connected components. This, in turn, reduces the frequency of maintenance and replacement, leading to cost savings and increased productivity.

- Smooth Power Transmission: Jaw couplings transmit power smoothly between the driving and driven shafts, resulting in less stress on components. The torsional flexibility of the elastomeric element helps prevent abrupt torque spikes, contributing to improved component longevity.

Overall, the jaw coupling’s ability to absorb shocks, compensate for misalignment, handle overloads, and provide smooth power transmission makes it an effective solution for minimizing wear and tear on connected components. Regular inspection and maintenance of the jaw coupling are still essential to ensure its optimal performance and extend the life of the entire mechanical system.

What are the factors influencing the thermal performance of a jaw coupling?

The thermal performance of a jaw coupling is influenced by several factors that affect its ability to dissipate heat and handle temperature fluctuations during operation. Here are the key factors that can impact the thermal performance of a jaw coupling:

- Material Selection: The choice of materials used in the construction of the jaw coupling plays a significant role in its thermal performance. High-quality materials with good thermal conductivity can efficiently dissipate heat, reducing the risk of overheating and premature wear. Common materials used in jaw couplings include steel, aluminum, and various elastomers.

- Elastomer Spider: The elastomer spider in the jaw coupling is a crucial component that can influence thermal performance. The type of elastomer and its specific characteristics, such as hardness and thermal conductivity, can affect the coupling’s ability to absorb and dissipate heat generated during operation.

- Operating Speed: The rotational speed of the coupling impacts its thermal performance. Higher operating speeds can generate more heat due to increased friction and stress on the coupling components. It is essential to ensure that the jaw coupling is rated for the specific operating speed of the application to prevent overheating and premature failure.

- Torque and Load: The torque and load applied to the jaw coupling can also influence its thermal performance. Higher torque and load levels can result in increased heat generation. Properly sizing the coupling based on the application’s torque and load requirements is essential to prevent excessive heat buildup.

- Operating Environment: The environment in which the jaw coupling operates can impact its thermal performance. For example, if the coupling is located in an area with limited airflow or high ambient temperatures, it may experience reduced heat dissipation capabilities. On the other hand, an environment with good ventilation can help in maintaining the coupling’s thermal performance.

- Lubrication: Some jaw couplings may require lubrication to reduce friction and heat generation. Proper lubrication can enhance the coupling’s thermal performance and extend its service life. It is essential to follow the manufacturer’s guidelines regarding the type and frequency of lubrication to ensure optimal performance.

- Continuous vs. Intermittent Operation: The thermal performance of a jaw coupling can also be influenced by the nature of its operation—continuous or intermittent. Intermittent operation allows the coupling to cool down between cycles, reducing the overall heat buildup compared to continuous operation, which may lead to higher operating temperatures.

Overall, careful consideration of these factors is crucial in ensuring the efficient thermal performance of a jaw coupling. Proper selection, installation, and maintenance of the coupling based on the specific application requirements can help prevent overheating, reduce wear, and prolong the coupling’s lifespan.

Limitations and Disadvantages of Using Jaw Couplings

While jaw couplings offer several advantages, they also have some limitations and disadvantages that should be considered when selecting them for specific applications:

- Angular Misalignment: Jaw couplings are sensitive to angular misalignment, and excessive misalignment can lead to increased wear and reduced service life.

- Radial Misalignment: Similar to angular misalignment, radial misalignment should be kept within acceptable limits to prevent premature wear.

- Temperature Limitations: The operating temperature range of jaw couplings may be limited by the material used. For high-temperature applications, other coupling types may be more suitable.

- Shock Load Absorption: While jaw couplings can handle moderate shock loads, they may not be ideal for applications with severe shock loads, which can lead to increased stress and failure.

- Torsional Stiffness: Jaw couplings have a certain level of torsional stiffness, which means they may not provide the same level of vibration isolation as other coupling types.

- Backlash: Jaw couplings can have some degree of backlash due to their elastomeric element, which may not be desirable in precision positioning applications.

- Speed Limitations: High-speed applications may require careful consideration of the jaw coupling’s design and material selection to avoid issues related to centrifugal forces.

Despite these limitations, jaw couplings remain a popular choice in many applications due to their ease of installation, simple design, and cost-effectiveness. Proper selection, installation, and maintenance can help mitigate some of these limitations and ensure optimal performance and reliability of the jaw coupling.

editor by CX 2024-04-26